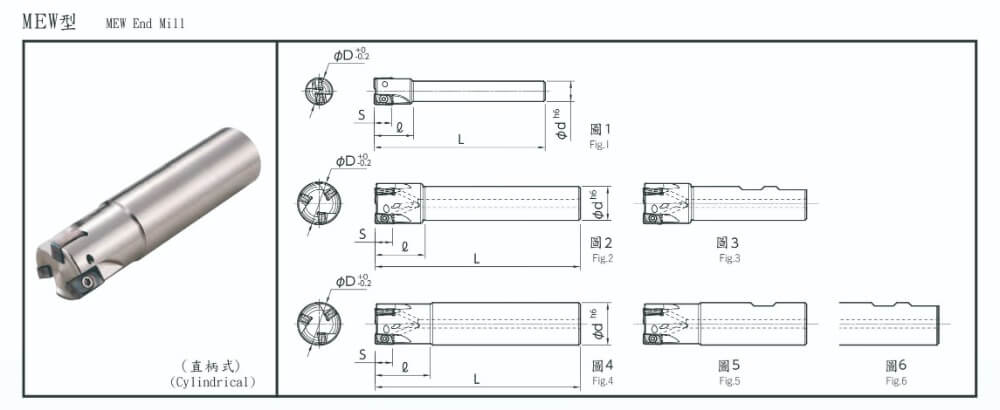

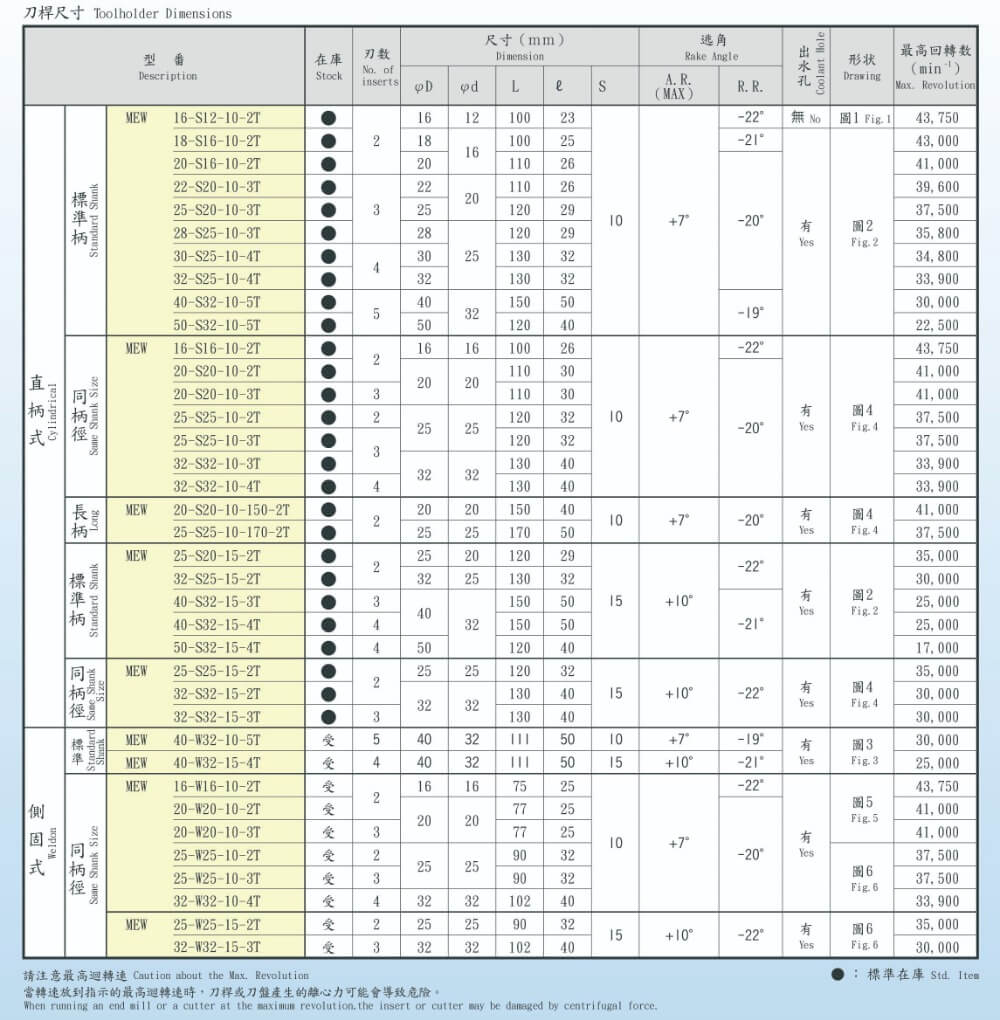

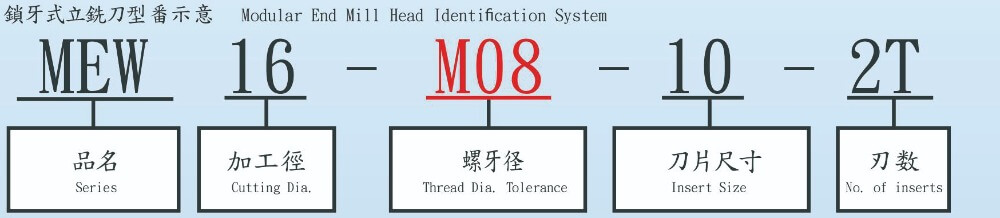

產品介紹

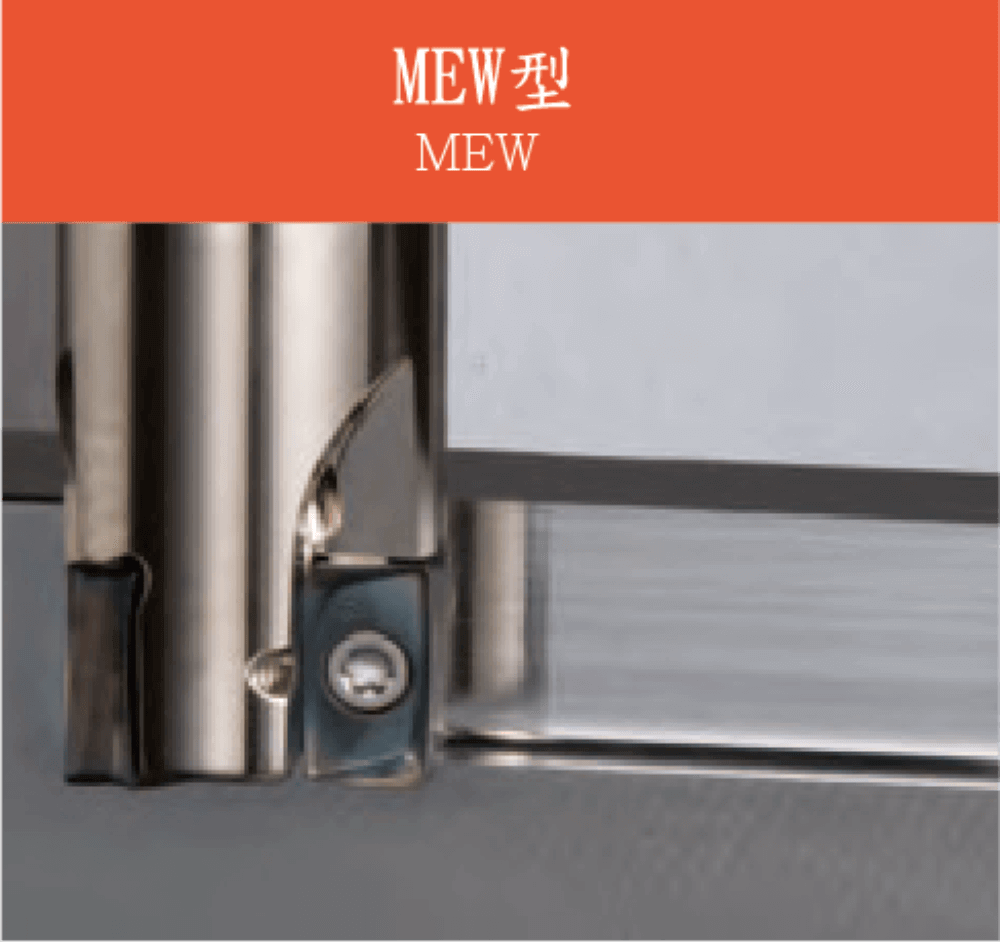

MEW Newly Developed Mold Technology End Mill

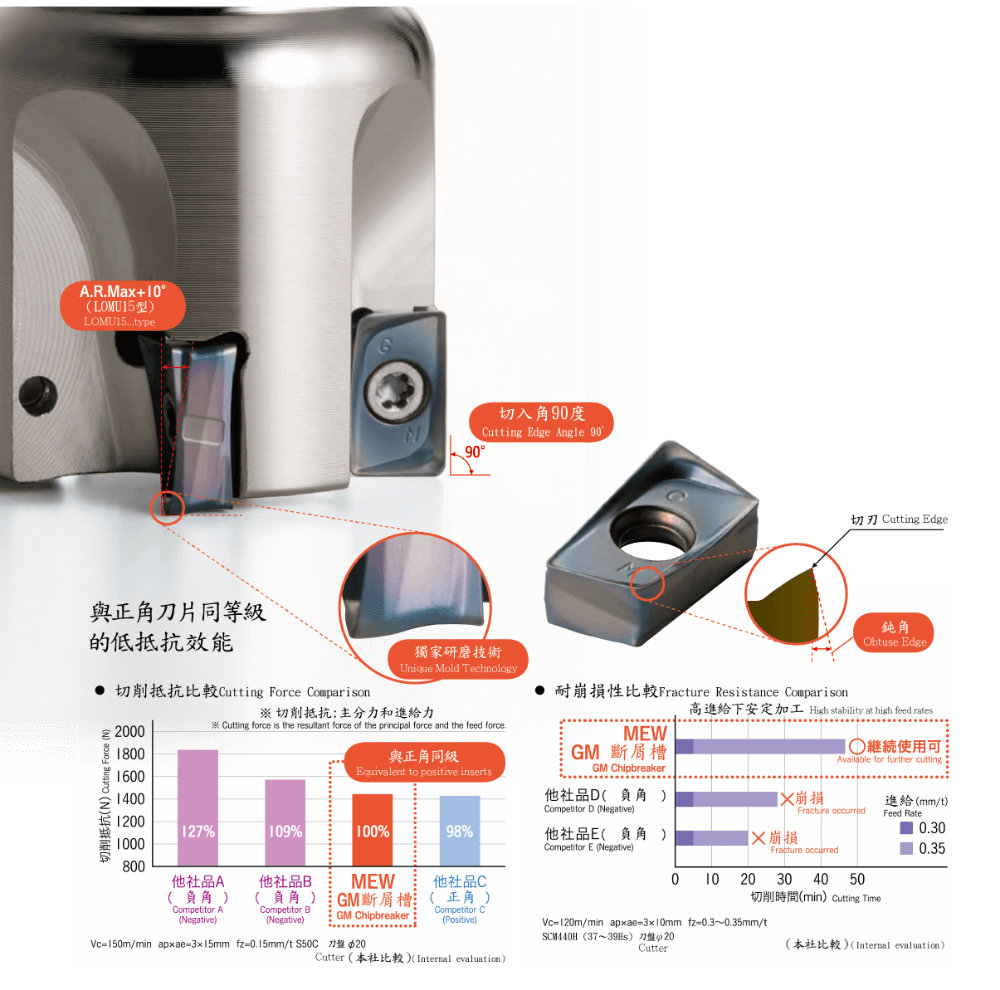

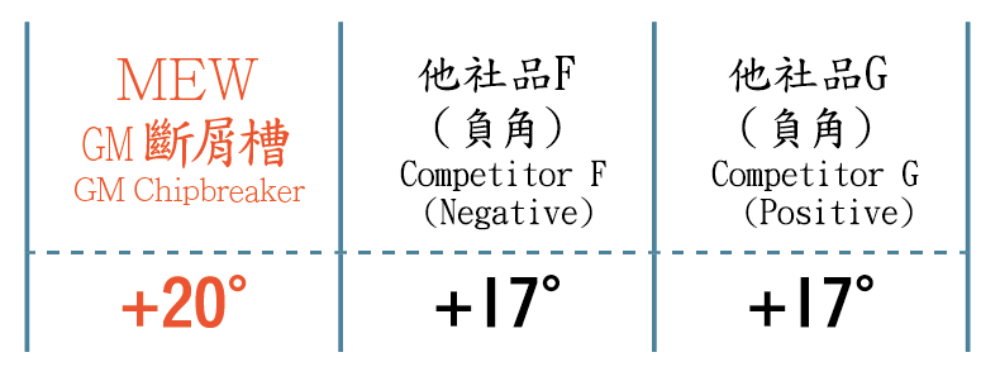

兩面四刃新世代立銑刀京瓷獨家研磨技術如正角刀片之低抵抗

Double-sided 4-edge Insert, Newly Developed End Mill Kyocera’s unique mold technology reduces cutting force equivalent to positive inserts

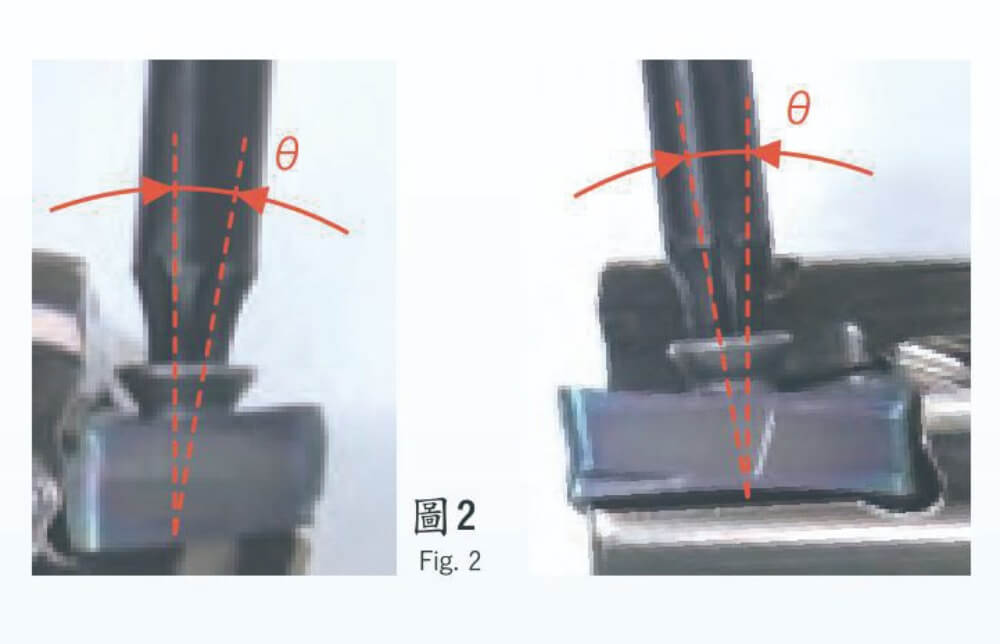

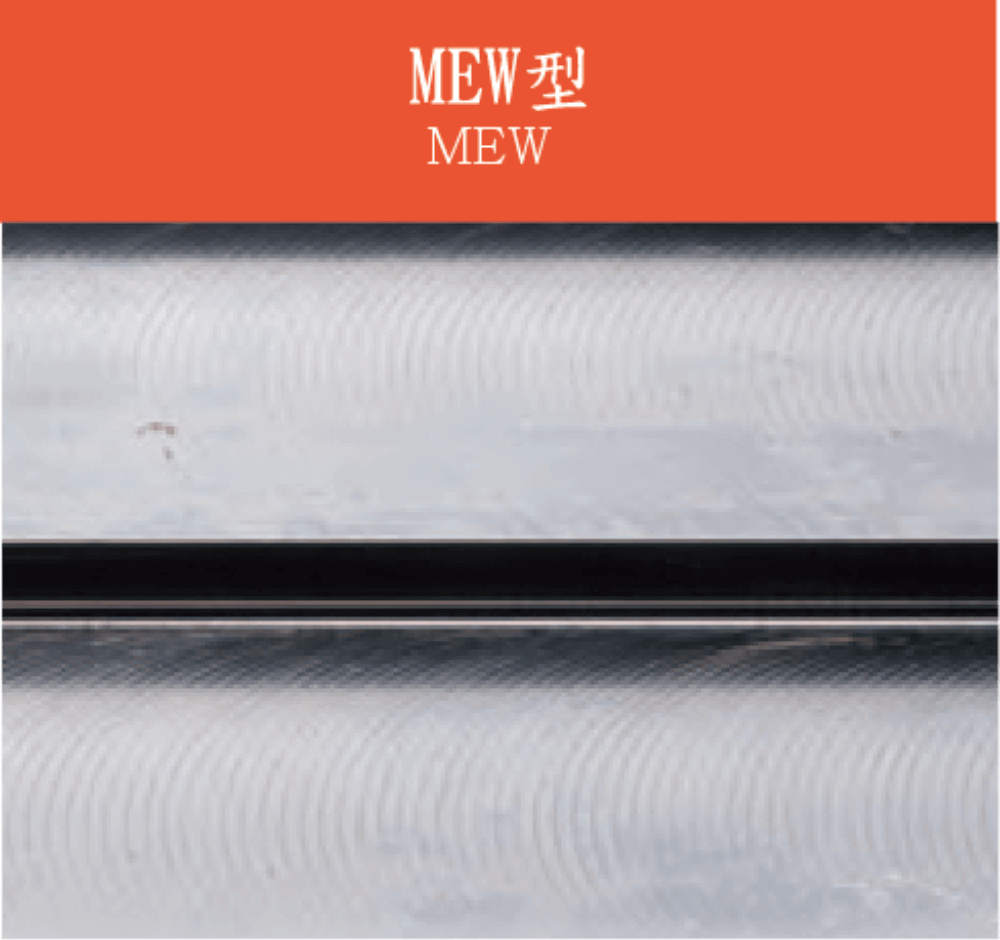

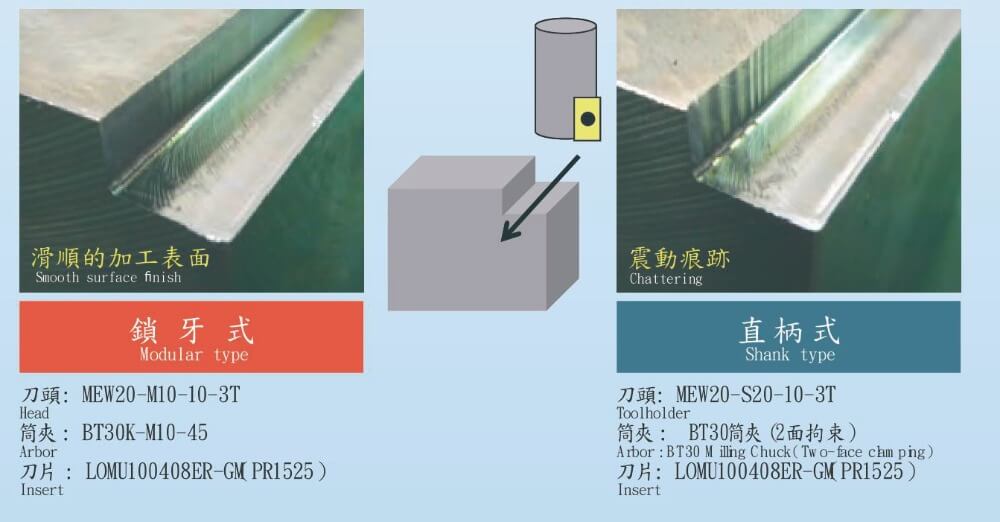

加強面粗,降低震動

Improved surface finish,minimzing chattering

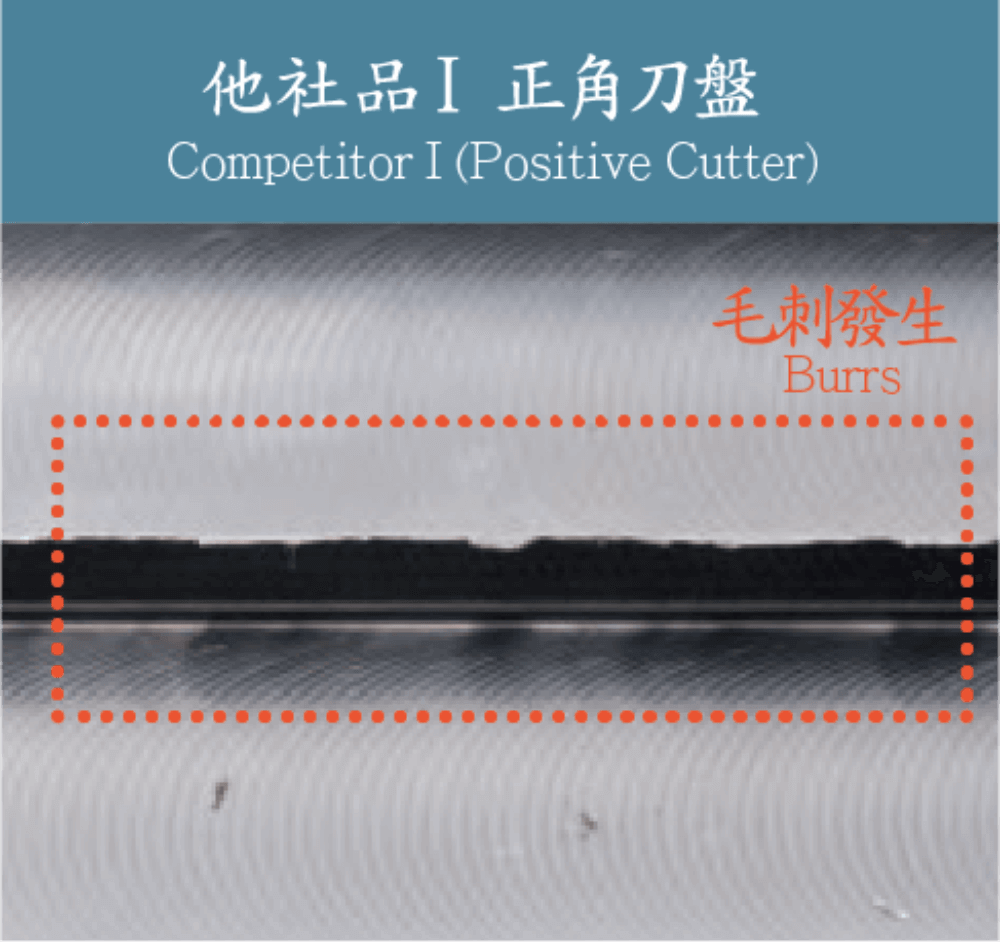

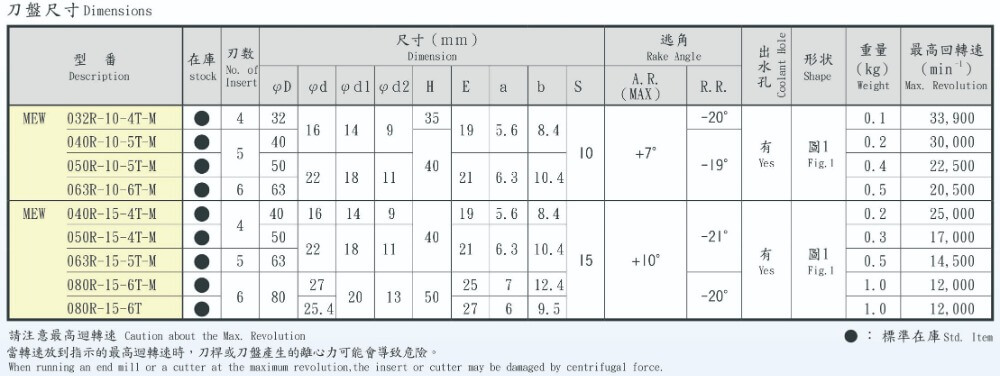

螺旋切刃和A.R.角度設計,使刀刃鋒利降低抵抗使振動和毛刺減少

Sharp cutting and superior resistance to chattering and burrs, due to helical cutting edge optimum axial rake design

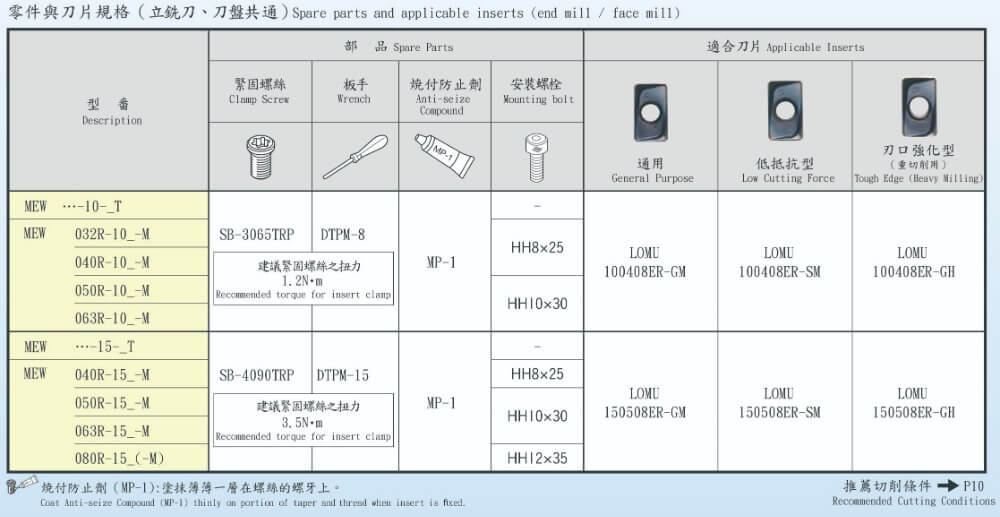

壁面的加工面狀態 Surface of Shoulder Wall

毛刺比較 Burr Comparison with Positive Cutters

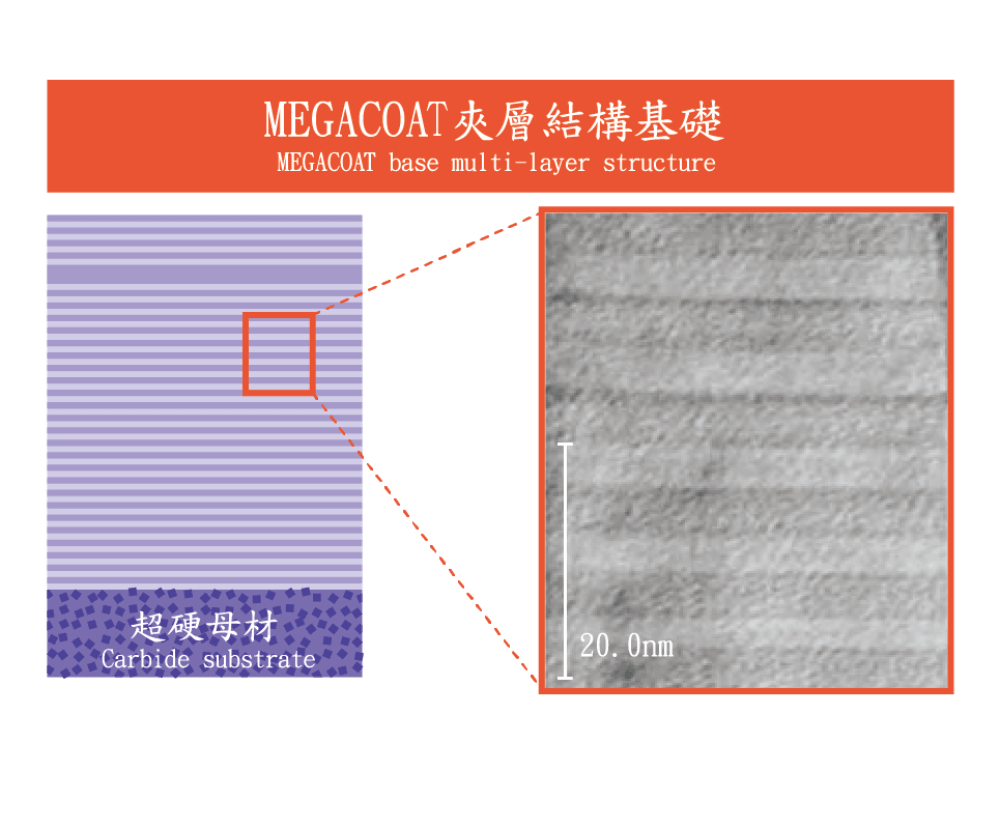

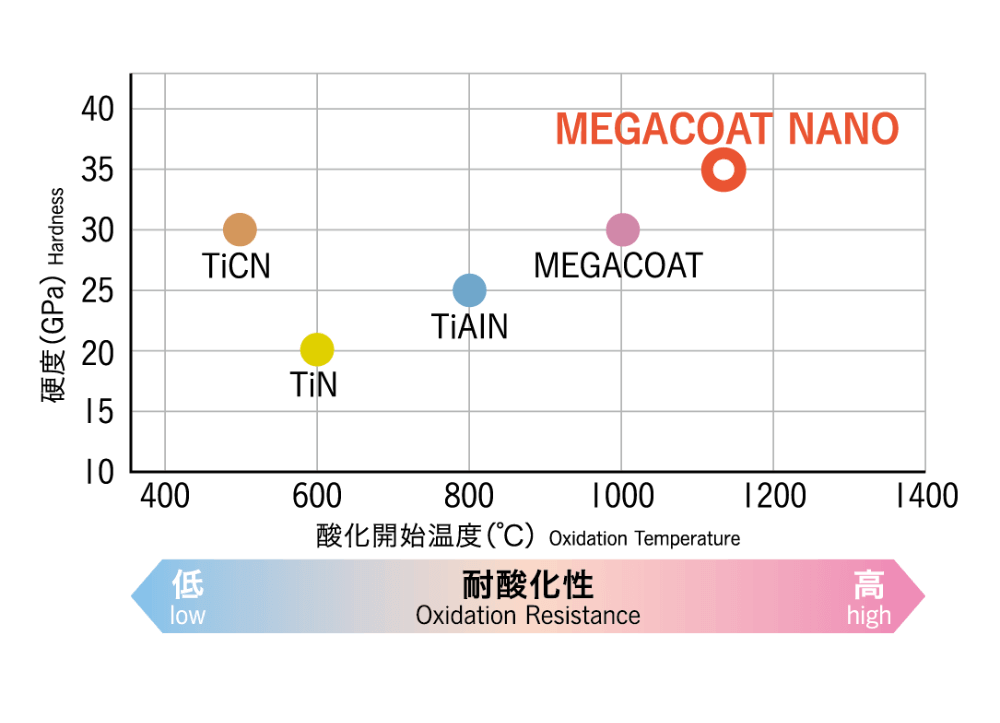

新技術MEGACOAT NANO 長壽命

Extended Tool Life by New MEGACOAT NANO Technology

特殊夾層結構「MEGACOAT NANO」使加工安定化並延長加工壽命

鋼不鏽鋼用PR1525鑄鐵用PR1510

Special multi-layer nano coating”MEGACOAT”enables stable milling and extended tool life PR1525 for steel and stainless steel, and PR1510 for cast iron

高硬度(35GPa)使耐酸化性(酸化開始溫度:1,150°C)

Prevents wear and fracture with high hardness (35GPa) and superior oxidation resistance (oxidation temperature: 1,150°C)

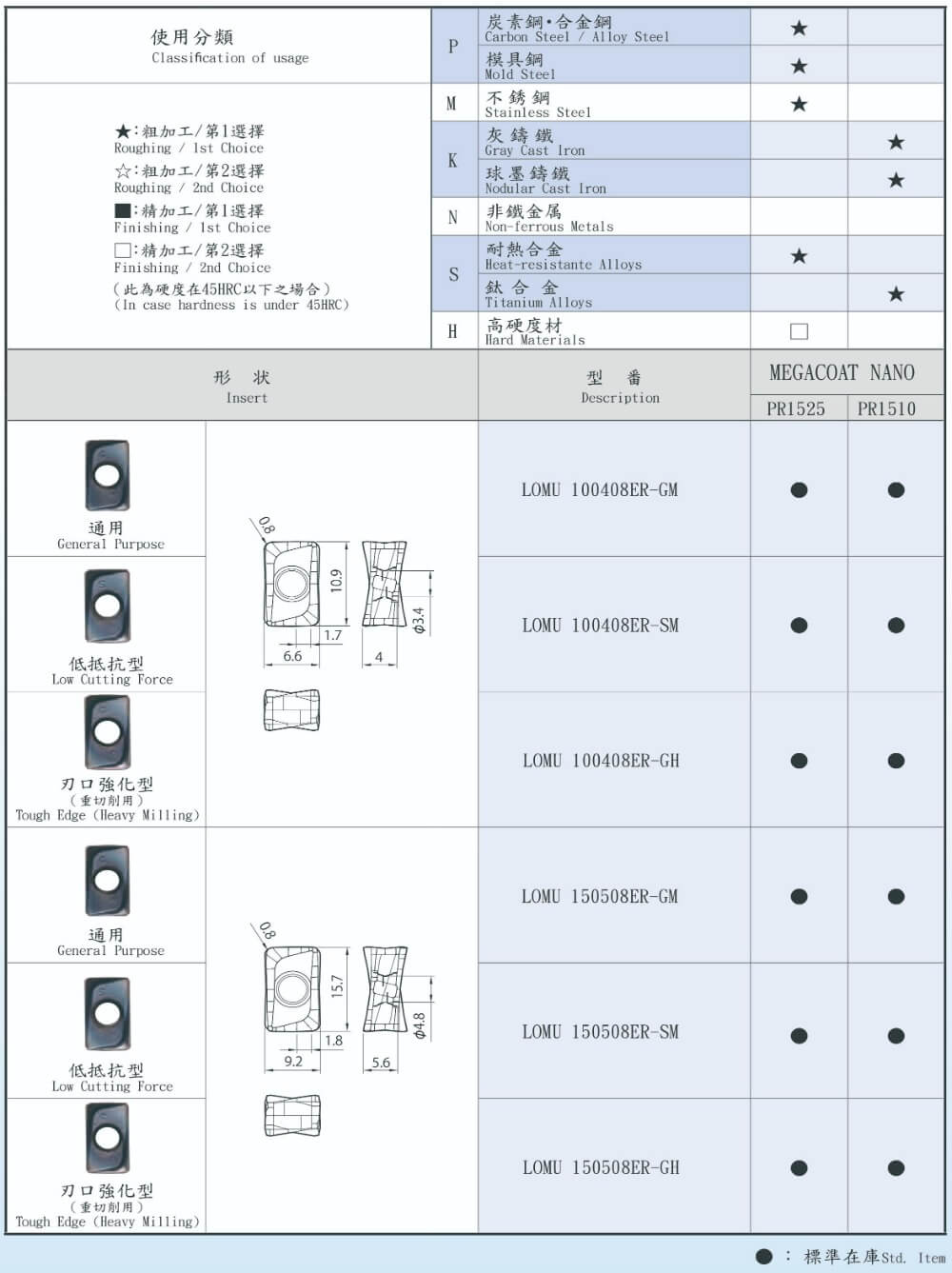

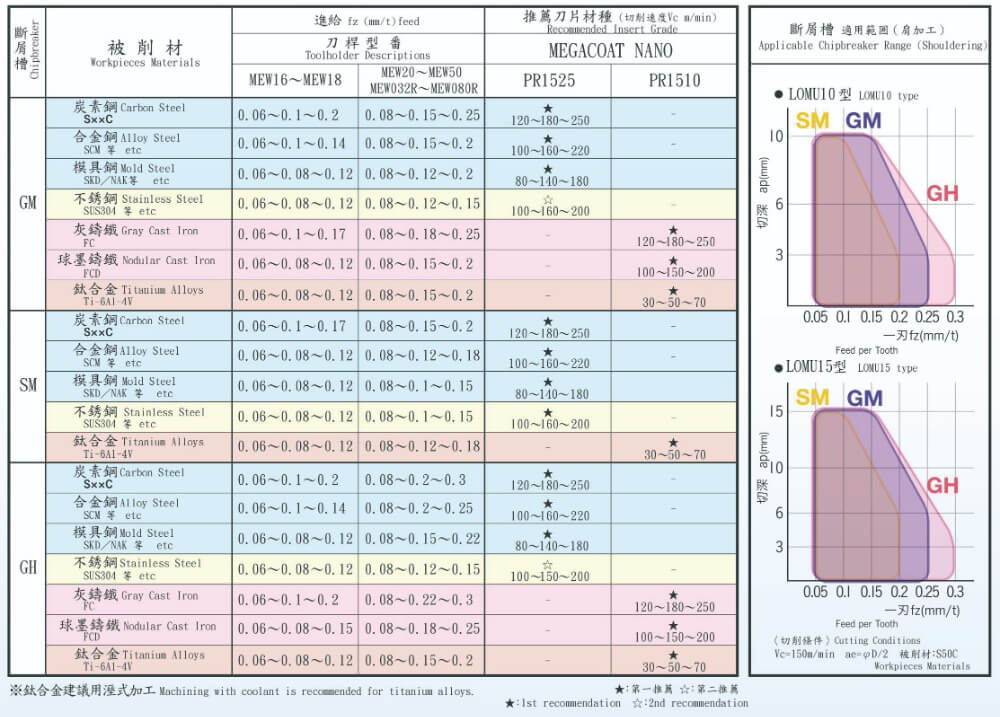

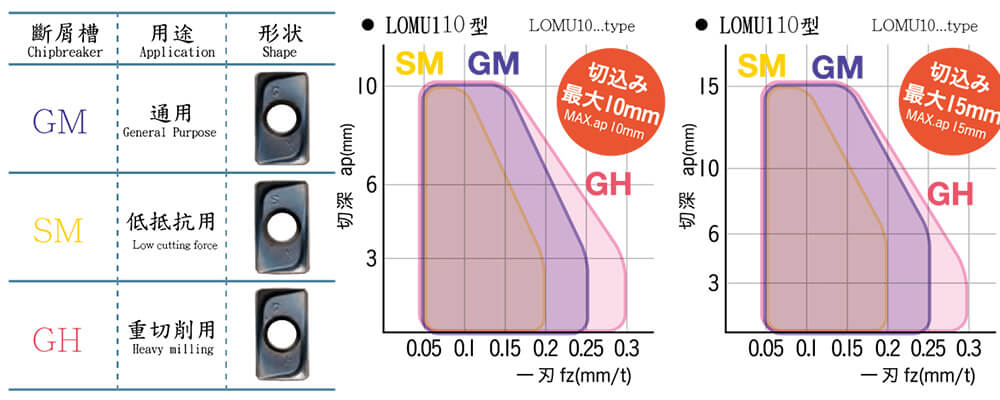

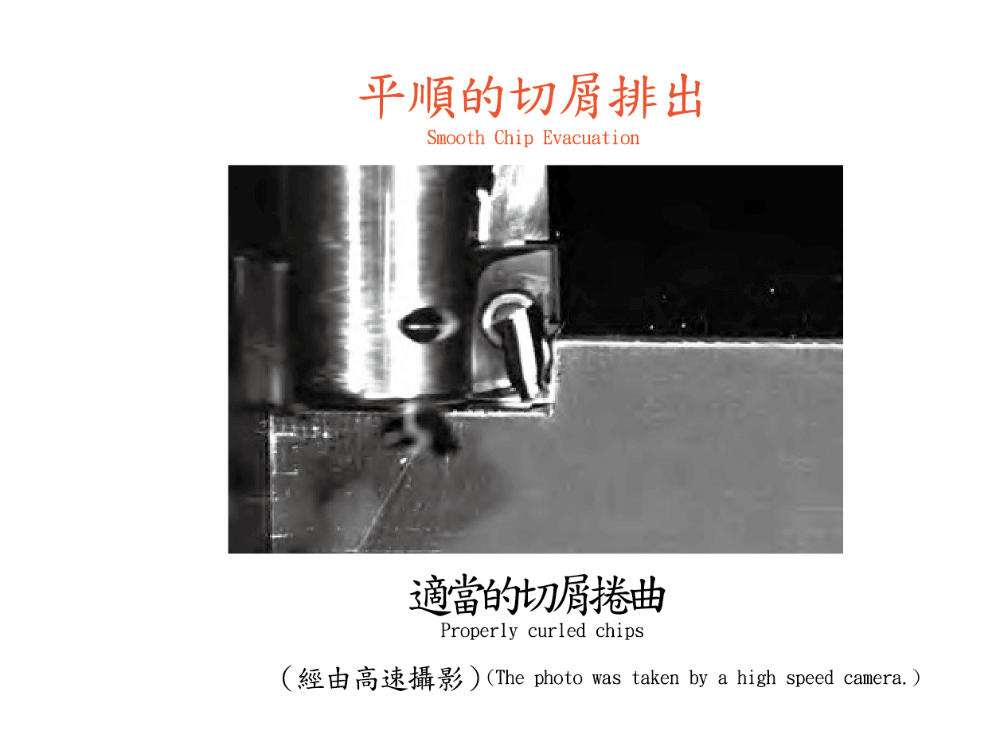

豐富的斷屑槽方案

Various Chipbreaker Lineup

新開發3種斷屑槽對應各種加工

Newly developed 3 chipbreakers for various applications

多樣化加工應用

Applicable to a wide range of application

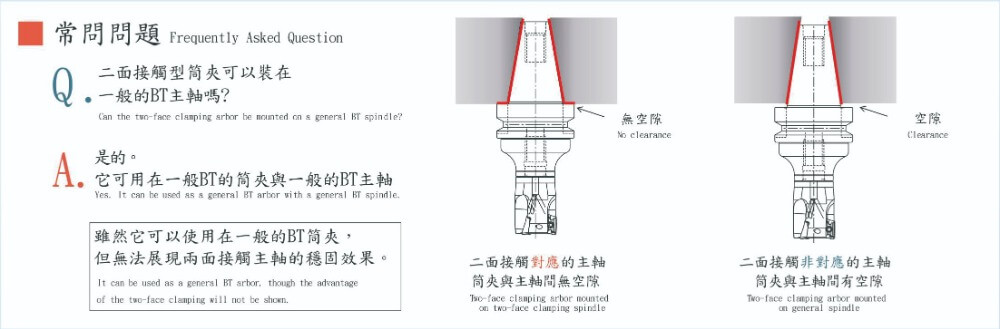

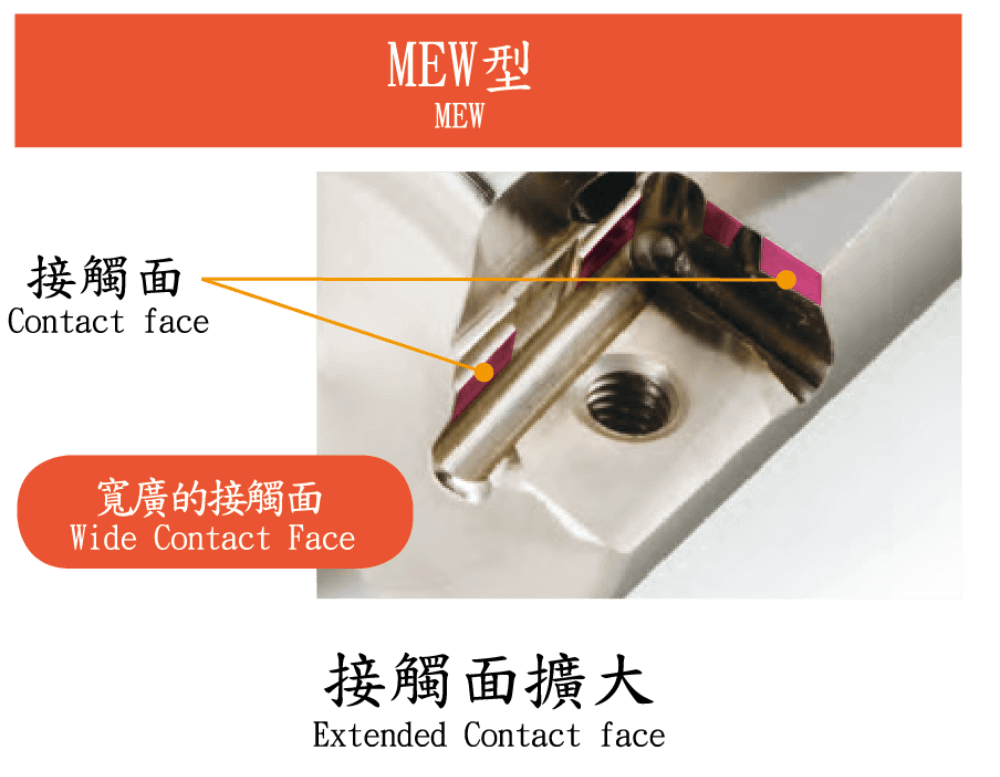

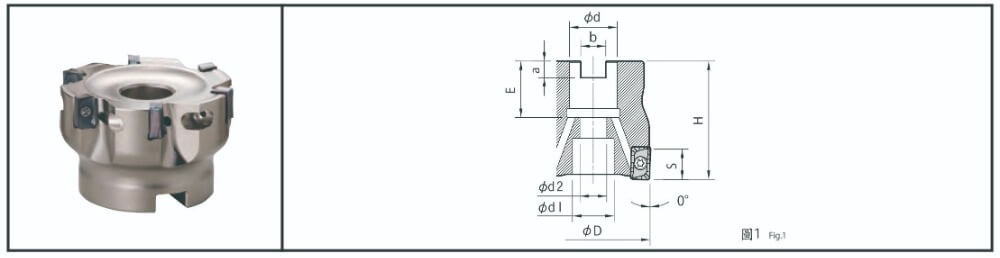

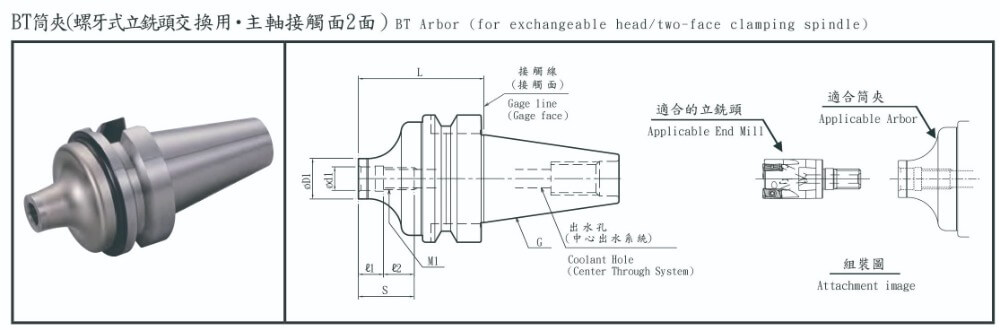

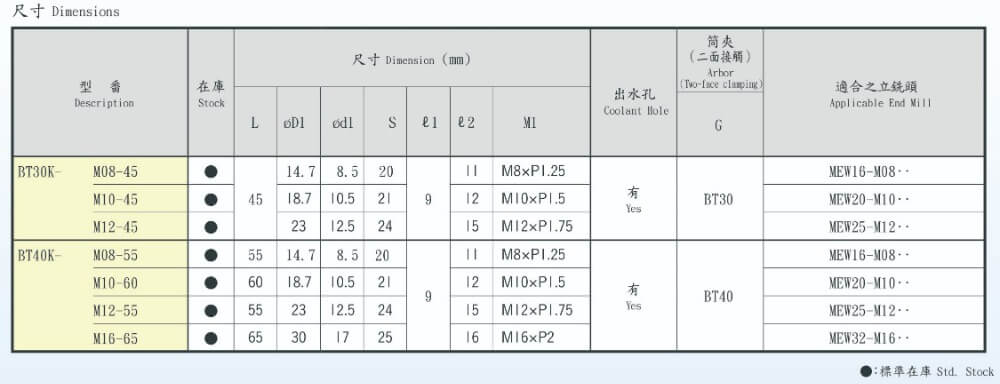

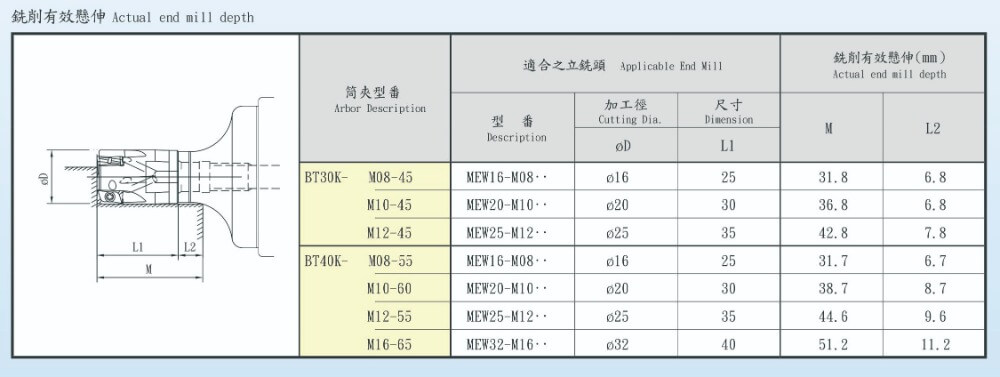

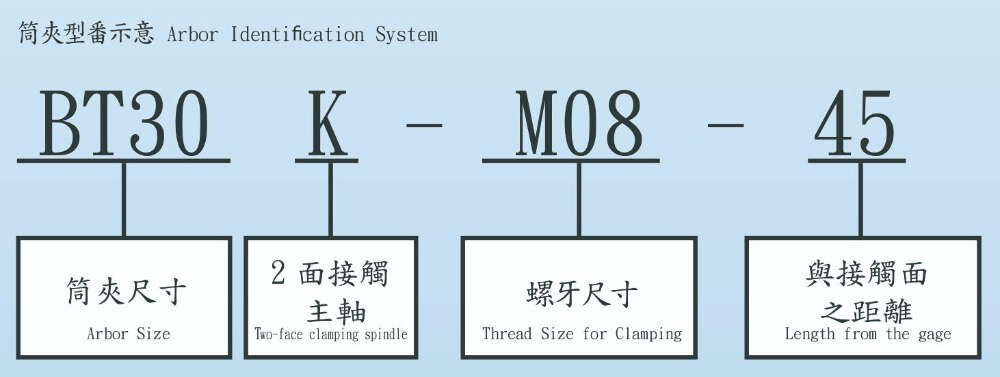

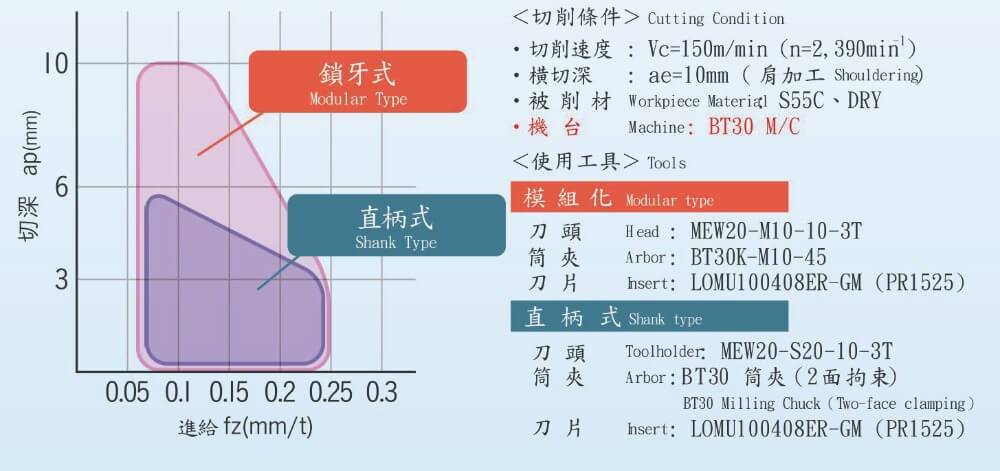

提升刀桿的耐久性和精度

Improved Toolholder Durability and Precision

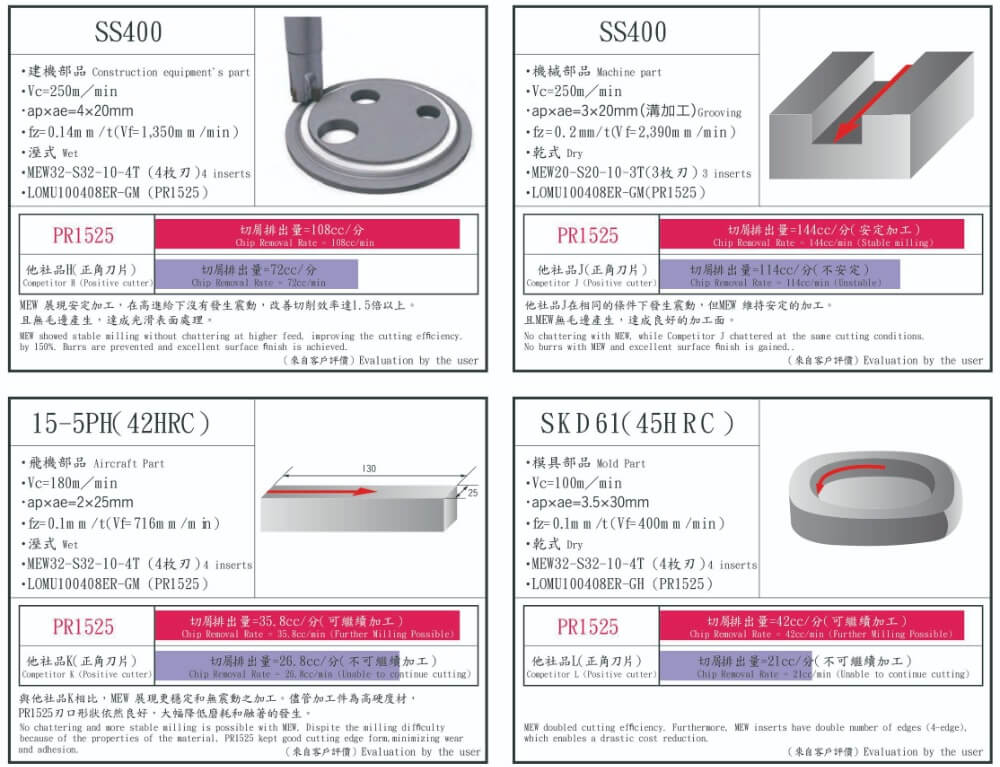

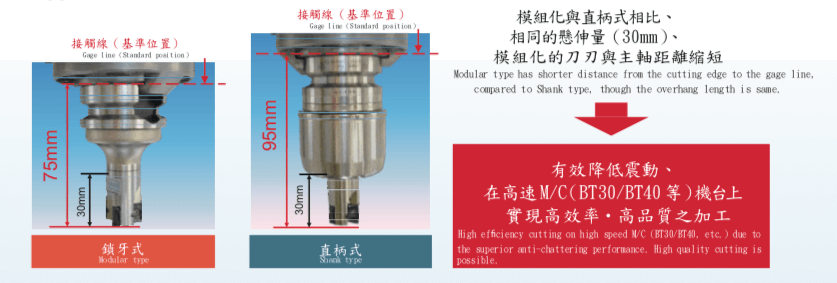

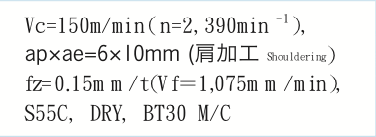

即使是BT30的機台也能加工出光滑的表面Smooth surface finish even in BT30/M/C

即使是BT30的機台也能加工出光滑的表面Smooth surface finish even in BT30/M/C