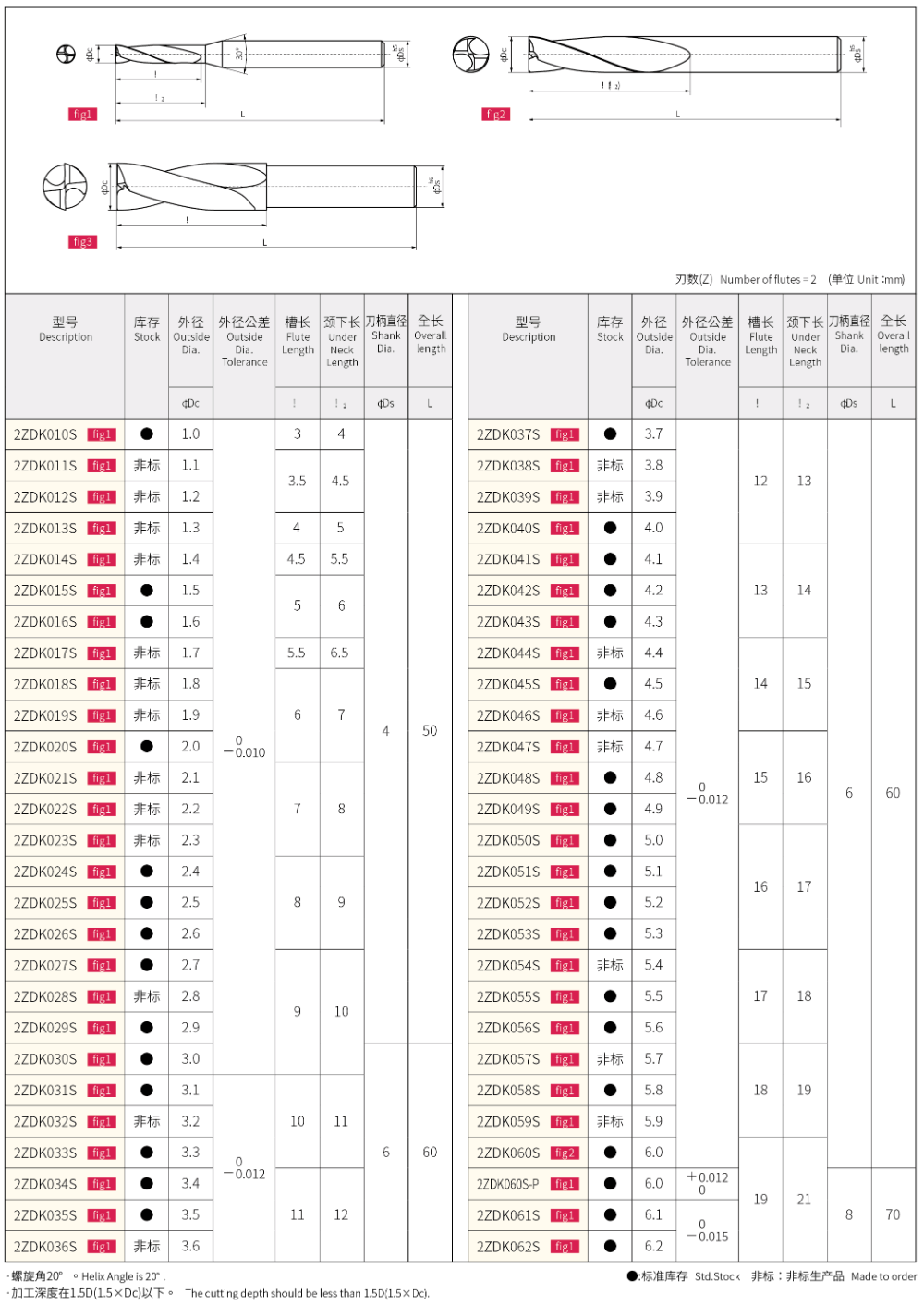

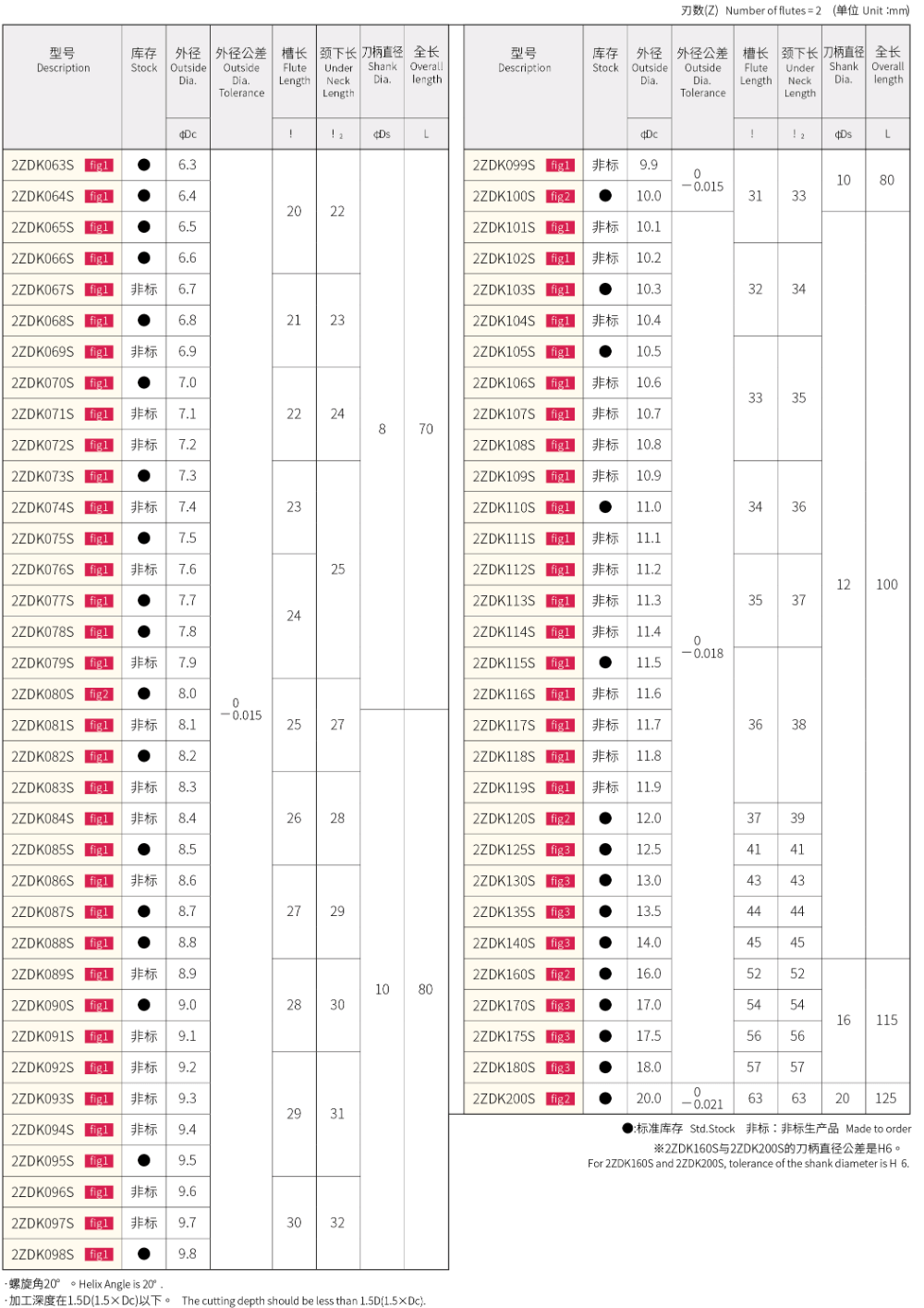

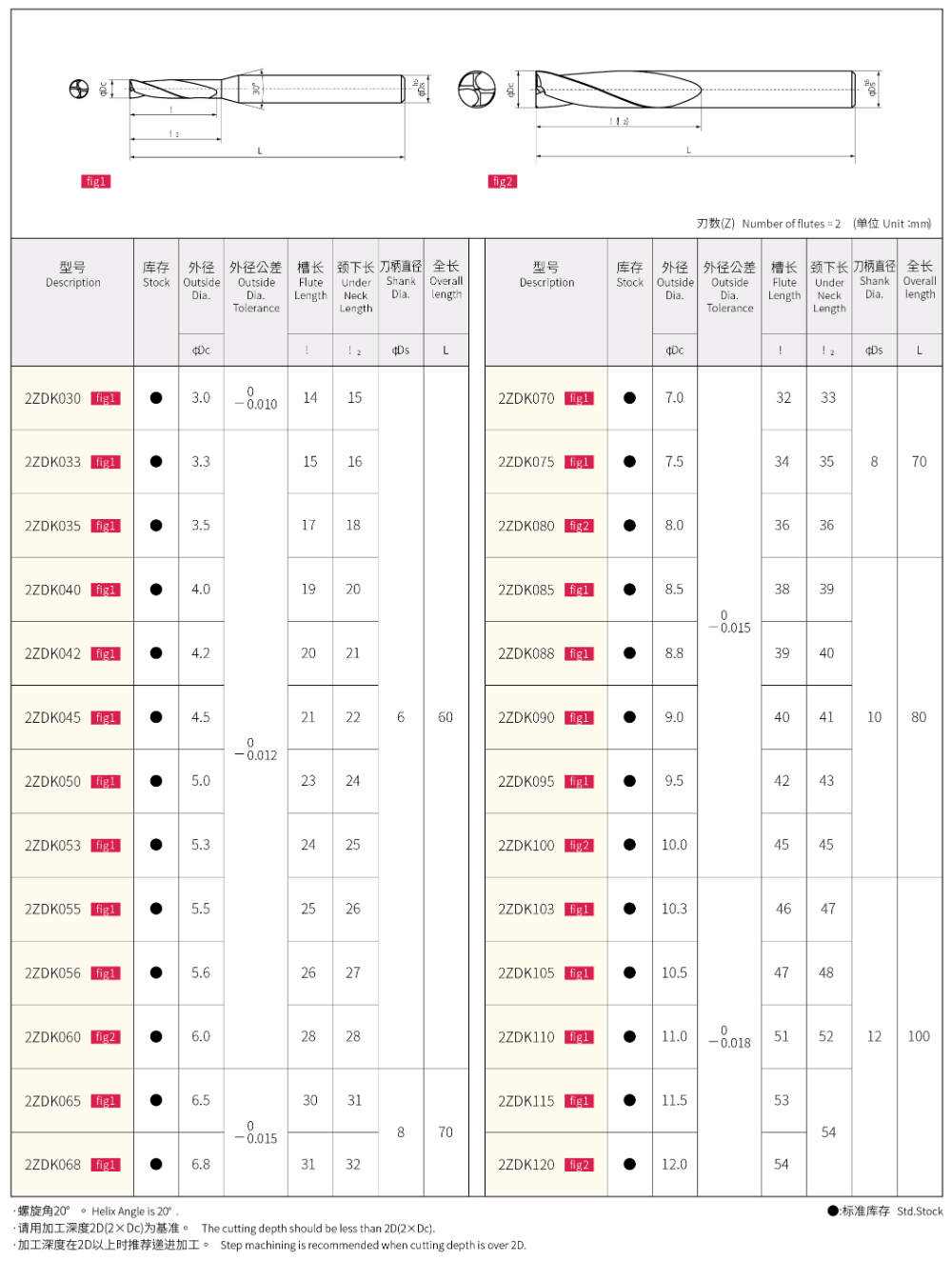

產品介紹

2ZDK

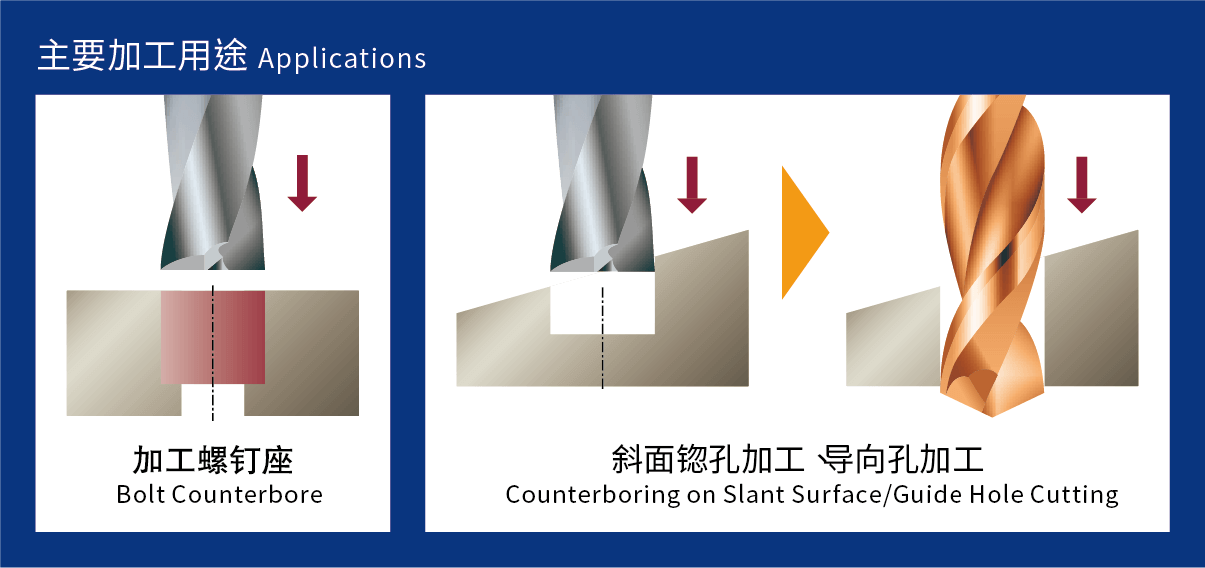

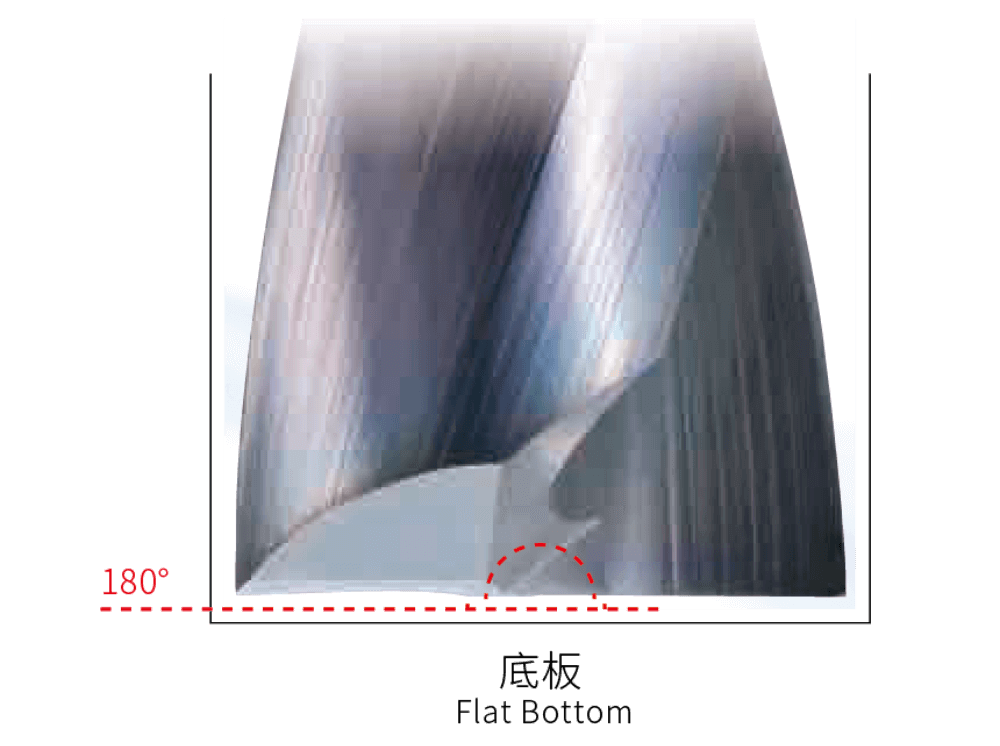

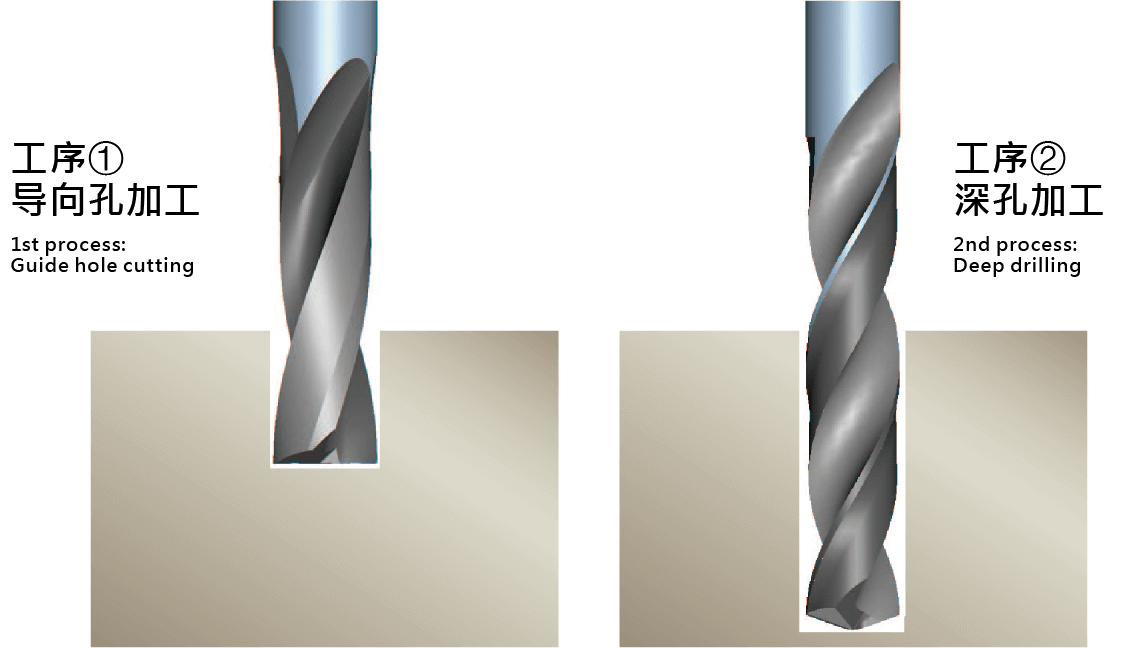

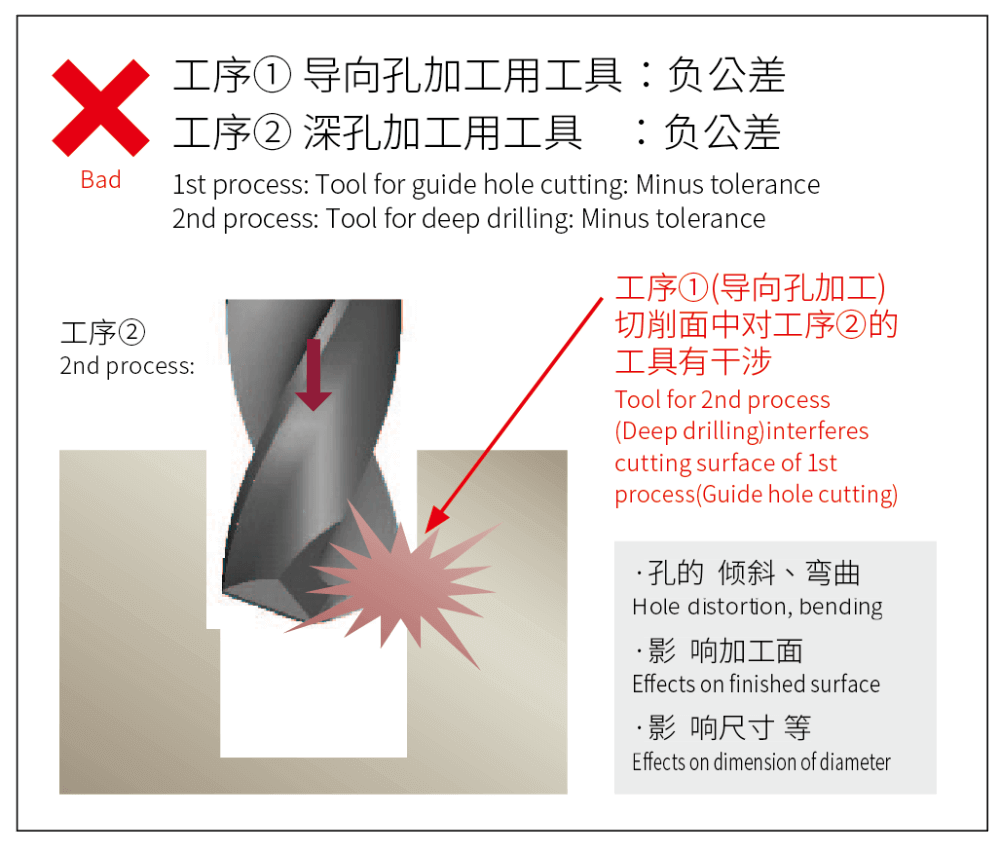

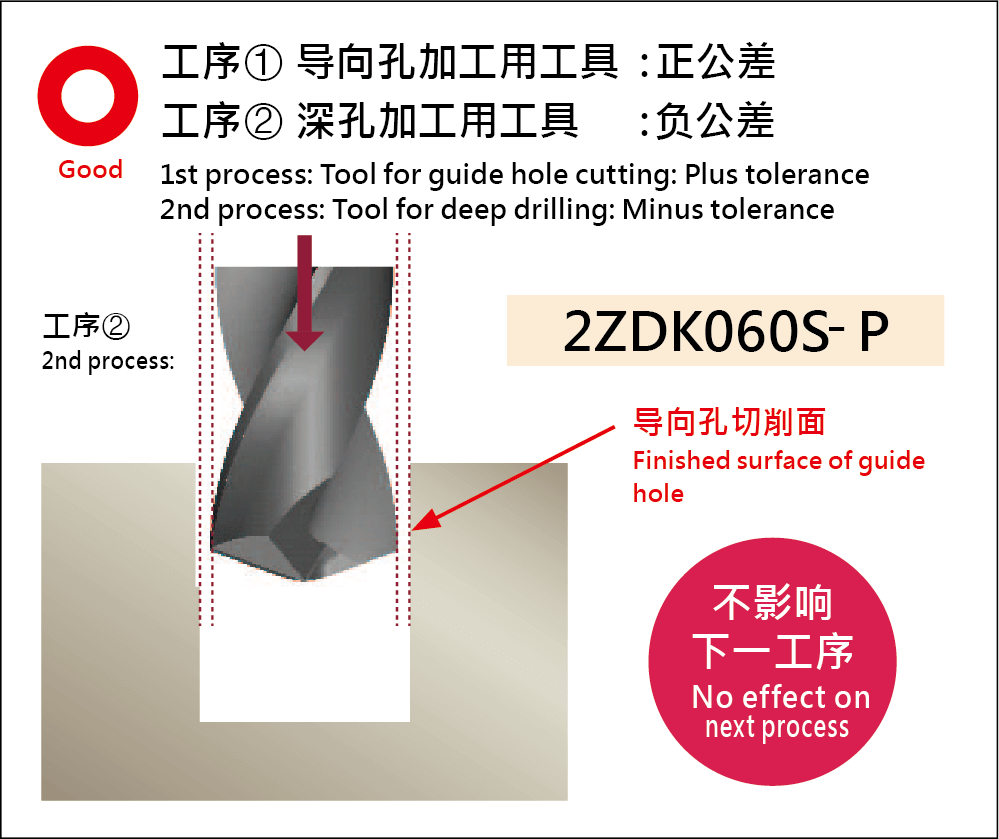

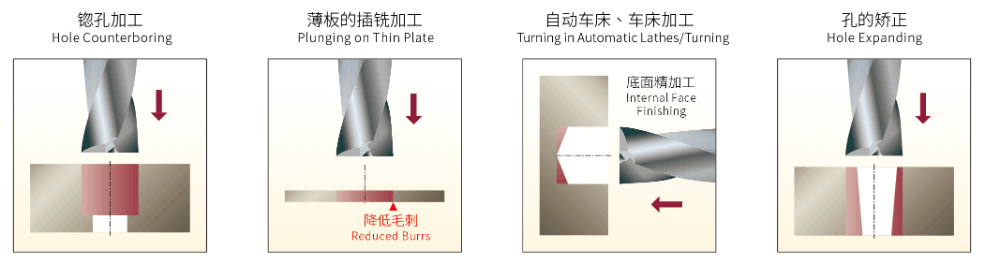

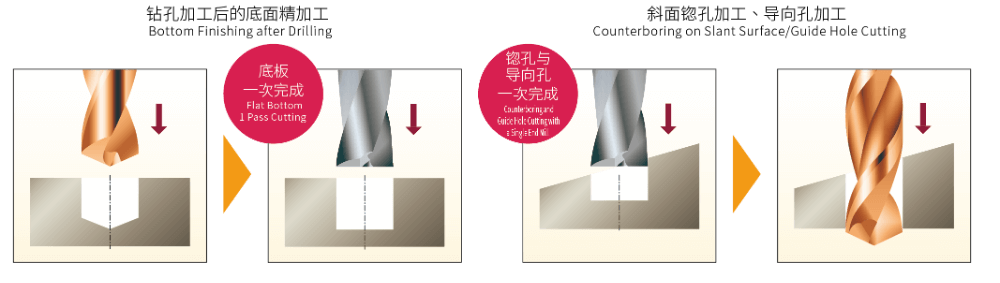

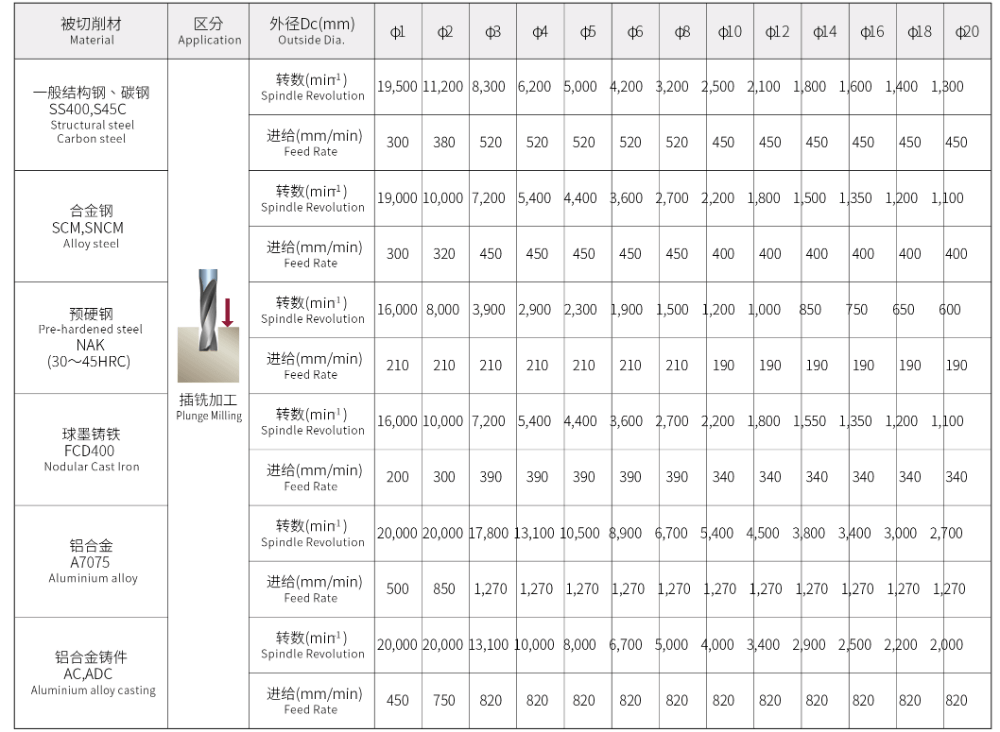

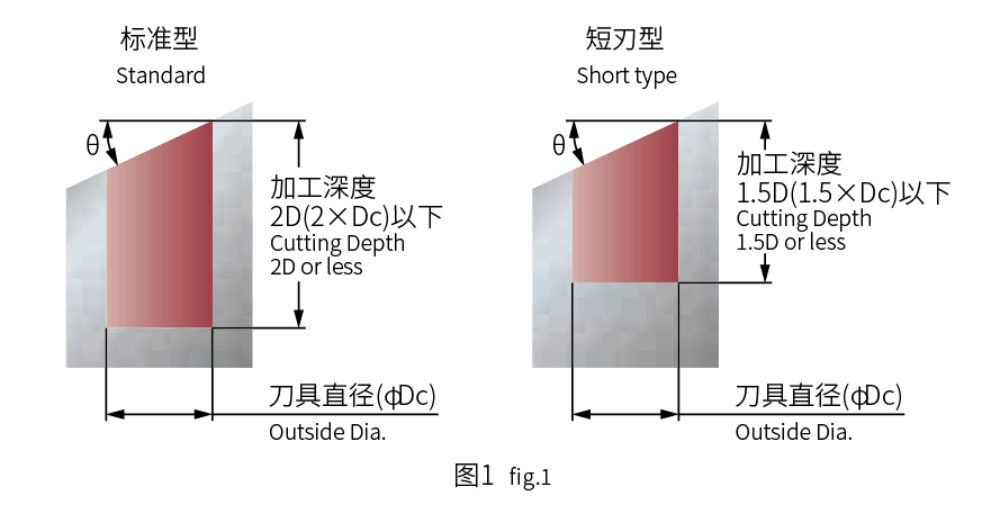

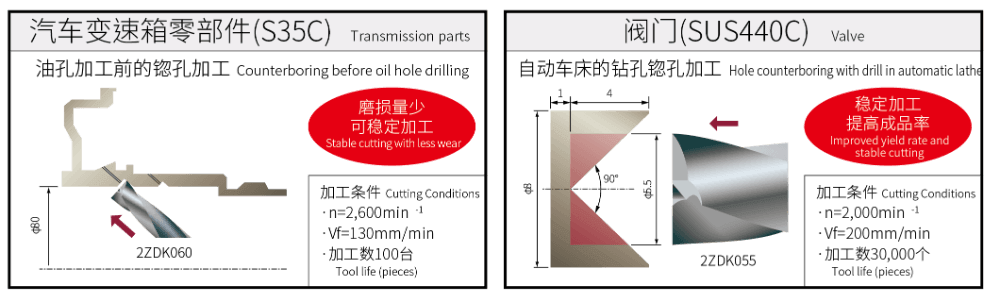

前端角180°平面可对立多样加工 可实现高精度锪孔加工 改善困难工序、降低成本的最佳刀具

Edge ends have 180° flat and are applicable to various applications. Available for high-precision counterboring. Optimum tool for improvement and cost reduction of difficult cutting processes.

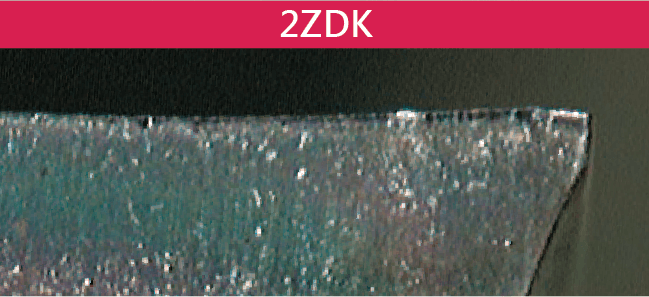

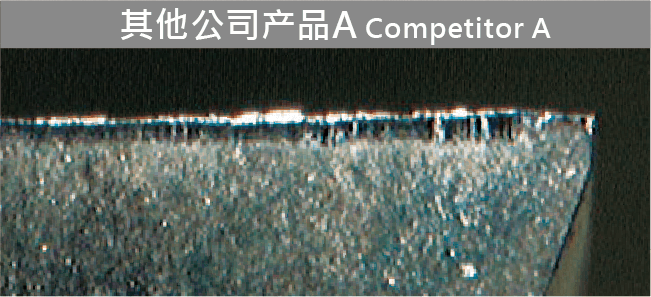

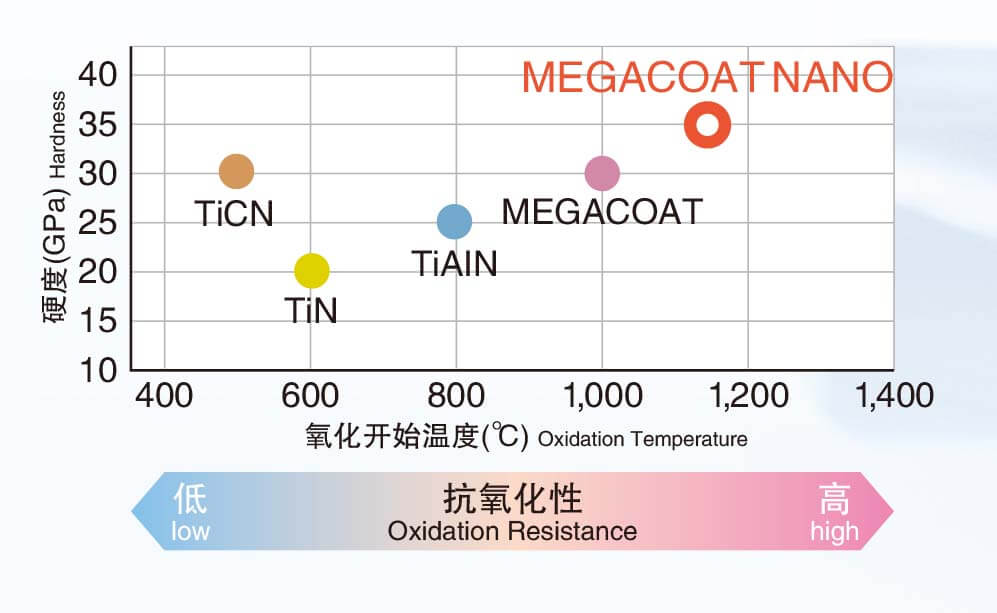

MEGACOAT NANO保证长寿命

Long Tool Life with “MEGACOAT NANO”

特殊纳米多涂层、高硬度(35GPa)与优越的 抗氧化性(氧化开始温度:1,150℃),可以抑制磨损、 提高抗崩刀性能。

The special Multilayer Nano Coating prevents wear and chipping with high hardness (35GPa) and superior oxidation resistance (oxidation temperature: 1,150℃)

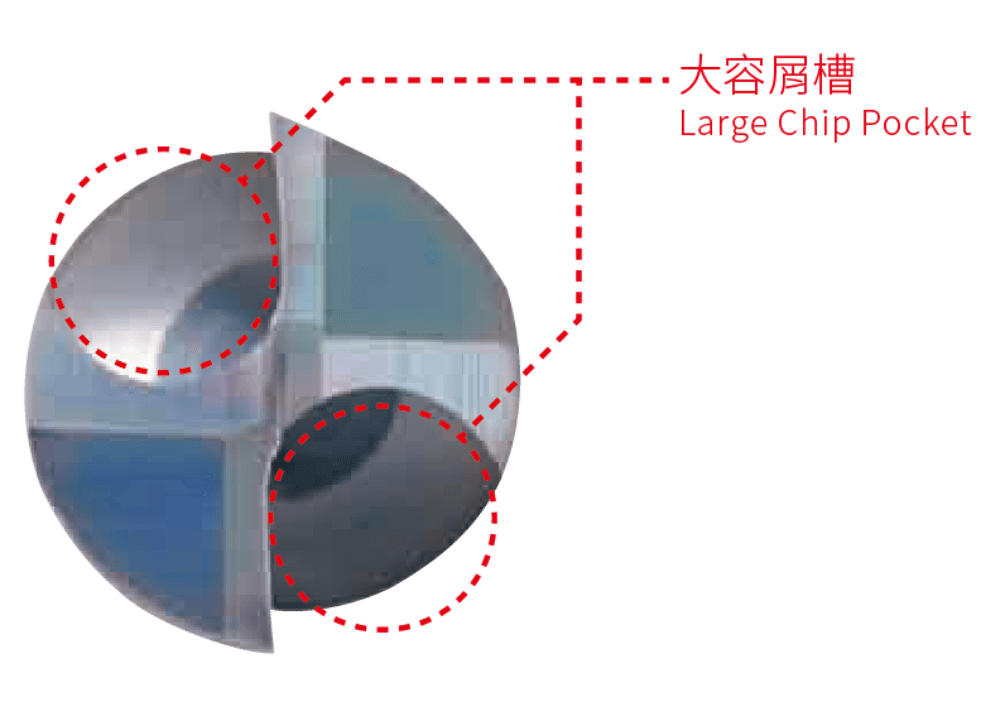

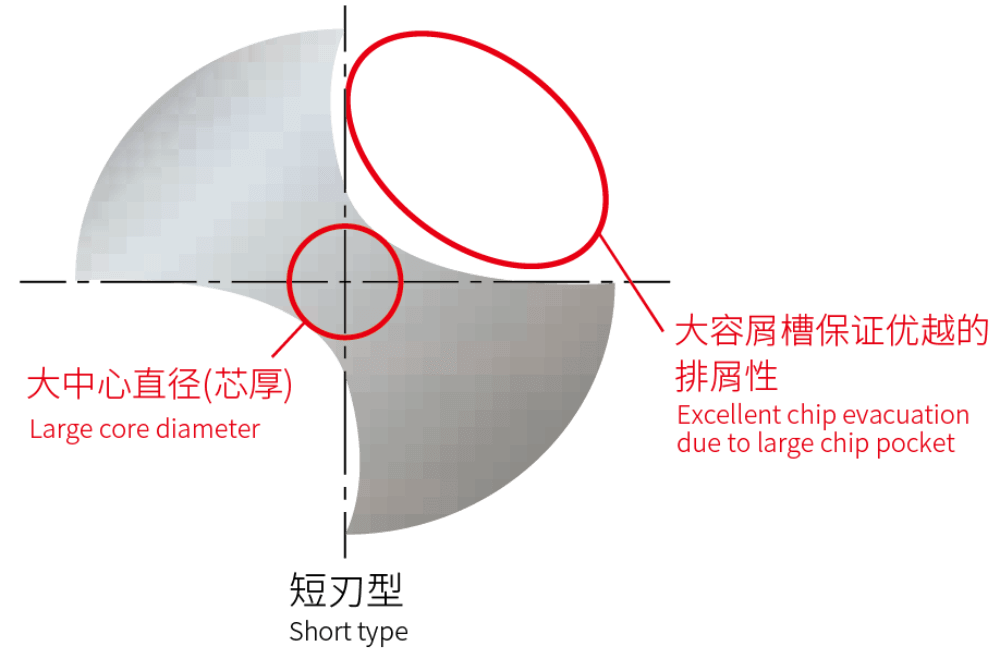

良好的排屑性

Smooth Chip Evacuation

特殊槽形保证良好的排屑性与高刚性同时实现

Combination of smooth chip control and high rigidity due to the special flute shape